Search...

Acrylic thickening agent is a flowing agent, which not only can deepen the coating, prevent flowing phenomena during construction, but also gives strong mechanical properties and storage stability with powerful coatings. For water -based coatings with lower viscosity, it is a very important type of auxiliary agent. Not only that, it is used in the manufacturing, storage, and use of water -phase glue adhesives and sealing agents. It can improve and regulate viscosity, and obtain stability, anti -precipitation, penetration, anti -drift, tactile change and other properties.

1. Cellulose thicker

Cellulose is a natural water -soluble polymer chemical. The principle of function is that the main chain of the hydrophobic chain is adsorbed to the surface of the latex particles to form a protective layer. Viscosity. This type of thickening agent is often used in the synthesis process of vinegar and cornea, which is used as a protective colloid and a blue light with a turbid white belt. The disadvantage is that the water resistance resistance of the coating film is worse.

2. Polyurethane thicker

Polyurethane thickeners have thicken water phase and latex particles. Because their molecular structures have hydrophilic groups and hydrophobic groups, they have a certain nature of surfactants. The water in the emulsion can form a beam, forming a mesh structure with the latex particles, making it difficult for the macromolecular chain to move and achieve a thickening effect. Such thickened agents can double the viscosity of thickening lotion, which is often used in the thickening of VAE emulsion. Add 5%to make the viscosity thickened from 5000MPA.S to 100,000 MPA.S. , No Blu -ray.

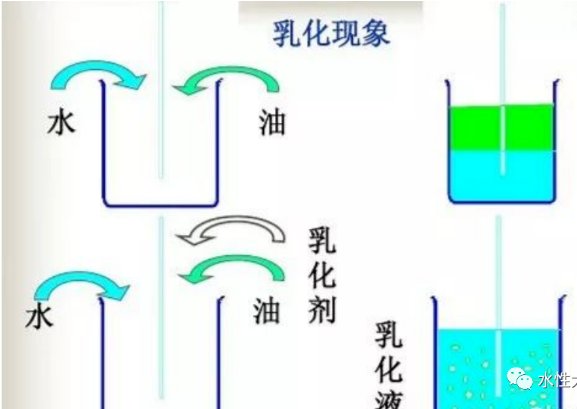

3. Emulsion agent

It is an indispensable component in lotion synthesis. Increases the amount of emulsifier in the reaction process. The rubber beam increases, the particle size becomes smaller, the charge between the rubber particles becomes stronger, and the viscosity increases. Taking a 60%solid printed plasma as an example, when the emulsifier content is 2%, the emulsion viscosity is 8000MPA.S. When the amount of emulsifier is increased to 4%, the emulsion viscosity becomes 14000MPa.s.

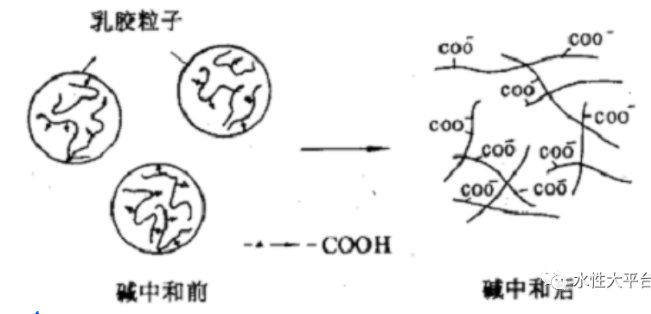

4. Alkaline bloating

The molecular chain contains carboxyl groups, which thickened the lotion by increasing alkaline substances such as ammonia water.

Most of the lacqued aggregation will be introduced in the carboxyl group. When under acidic conditions, the emulsion pH is low, and the carboxyl of the latex particles on the surface of the latex particles cannot be ionized. Except for the ionic emulsifier ionizer on the large molecular chain In the middle, the gum is not interfered with. As the pH becomes high, the carboxyl base of the surface of the glue particles, the latex particles start to absorb water and swell. When the alkaline substances added, the carboxyl group completely disintegrates. The extension of the water molecules entered the extension of the particle extension to make the surface size larger, hindering the liquidity of the molecule, and the viscosity of the entire lotion system.