Search...

1. viscosity

(1) The paint itself has a great viscosity and the construction effort.

(2) The customer needs to be smaller viscosity to facilitate construction.

Solution: It is recommended to use a rubber or metal scraper to scrape the construction, and it is not advisable to use roller coating or brushing. If you add a diluent, you should do a small test first.

Reminder: Of course, it is recommended to try not to add diluers as much as possible.

Second, a large amount of bubbles or small holes appear in the coating film

In the following cases, a large amount of air bubbles or small holes are prone to appear in the coating film:

(1) The weather is humid or rainy. Do not construct on humid or rainy days. After the rain is dry after rain, it must be constructed after the grassroots dryer. After construction, rainproof measures should be taken.

(2) Customers add a low -boiling dilute agent at the time of use, and the diluent is quickly volatilized and prone to bubbles or small holes.

Solution: For the above reasons, a large number of foam or pores are produced, it is recommended to eliminate the remake, or wait until the coating film is dry.

Third, the coating film is not dry or dry; no strength or strength is not enough

In the following cases, the coating film is prone to hair sticky, not dry or dry, no strength or insufficient strength, etc.:

(1) Polyurethane is usually dry and slower at low temperature. Generally, the drying time is about 24 hours, and it takes 2 days or longer to dry at low temperature (depending on the specific temperature and humidity). The lower the temperature, the longer the drying time.

(2) Add inappropriate diluents or use non -dry containers will affect the dryness and performance of the product.

Solution: If the above phenomenon occurs after construction, it has affected the waterproof performance and needs to be eliminated.

Fourth, the problem of drumming or falling off with the grassroots after the film formation

The main reasons for the problem of drumming or falling off with the grassroots after coating film:

(1) Loose or ash or oily substances at the grassroots level, such substances should be completely removed before construction.

(2) Using inappropriate grassroots treatment agents (such as cold base oil), it is strictly forbidden to use inappropriate grassroots treatment agents.

(3) There are water or humidity at the grassroots level, and the grassroots should be built after the grassroots are dry.

(4) The coating film is closed or the protective layer is performed without completely drying.

Solution: After the coating is made, the drum is drum or falls off with the grassroots, and the drum or falling part needs to be eliminated. If necessary, the grassroots treatment should be re -treated.

5. There is a skin problem on the surface of the product

The possible cause of the skin:

(1) Packaging deformation or damage.

(2) The customer has been placed for a long time after opening, but does not adopt a reasonable sealing method.

Solution: Generally, as long as it is not completely solidified, the surface of the surface can be removed, and the following part can be used normally.

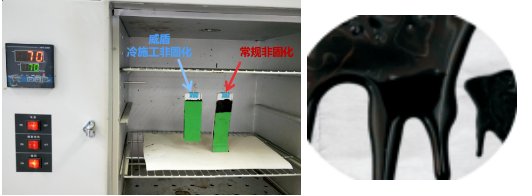

Cold construction non -curing construction advantages:

• Cold construction

AB material ratio, simply stirless, no need to heat, and cold construction.

• High temperature does not flow

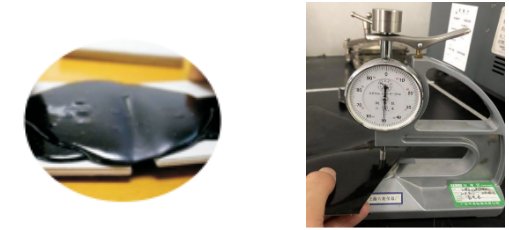

High temperature resistance above 80 ° C can be used for exposed waterproof projects.

• High solid

More than 95%of the high -solid content, low material consumption, and coating film quality guarantee.

• Construction

Construction in place at one time, no need to wait, save construction periods.

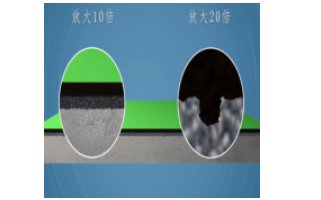

• High stripping

The grassroots and coating layers, coils, and coating layers react to bond, not easy to peel off, long -term reliability.

• Water -proof

Fusion composite waterproof layer, efficient anti -watering.

• Simple construction

It can be sprayed and scraped.

• Safe and environmentally friendly

There is no volatilization of personnel and environmental friendship.

Scope

Commonly used for waterproof parts of the underground, roofs and other waterproof parts of civil and industrial buildings, as well as waterproof projects for municipal projects.